Introduction

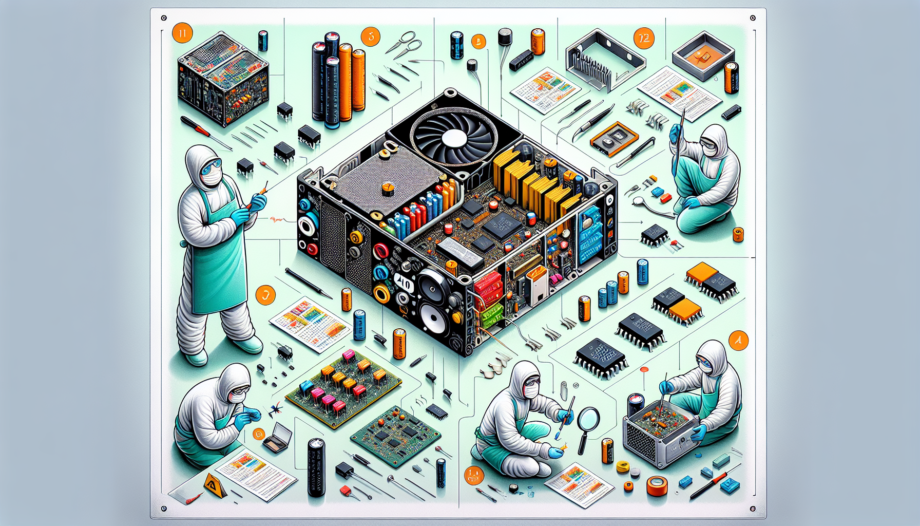

Get ready to dive into a step-by-step guide on repairing the 410 Duo device. This repair process involves identifying and replacing a faulty component that is causing the device not to power up. Through the use of testing equipment and technical knowledge, the repair is carried out efficiently to ensure the device functions properly once again.

Follow along as the technician troubleshoots the issue, locates the problematic component, finds a suitable replacement, and successfully completes the repair. Witness the device being reassembled and powered on, showcasing its restored functionality. Discover the intricate process of diagnosing and fixing electronic devices, gaining insights into the world of electronics repair.

Initial Assessment of the Device

Upon initial inspection of the 410 Duo device, the technician identified that it was not powering up and had visible signs of being disassembled. The technician quickly diagnosed a faulty capacitor on the input side, leading to further investigation. Upon removing the heatsink, it was discovered that one of the mosfets was burnt, causing additional shorts on the board.

After identifying the faulty mosfet, the technician proceeded to find a suitable replacement with similar specifications. Through testing and comparing data sheets, a compatible mosfet was found and successfully installed. With the new component in place, the device was powered on, and fan spin was observed at eight volts, indicating a successful repair.

Once reassembled, the 410 Duo device powered on correctly, displaying voltage readings and functioning as expected. The thorough diagnostic process showcased the importance of identifying and replacing faulty components to restore functionality to electronic devices successfully.

Identifying the Issue

During the initial assessment of the 410 Duo device, the technician observed that the device was not powering up and showed signs of being disassembled. Upon further inspection, a faulty capacitor on the input side was identified, leading to additional investigation. Upon removing the heatsink, a burnt mosfet causing shorts on the board was discovered.

The technician then located a suitable replacement mosfet with similar specifications through testing and comparing data sheets. After successful installation, the device was powered on, and fan spin at eight volts indicated a successful repair. The thorough diagnostic process highlighted the importance of identifying and replacing faulty components to restore functionality to electronic devices effectively.

Testing and Diagnosing the Faulty Component

Once the technician identified the 410 Duo device not powering up and visibly disassembled, they began the diagnostic process. Upon inspection, a faulty capacitor on the input side was discovered, leading to further investigation. Removing the heatsink revealed a burnt mosfet causing additional shorts on the board.

After pinpointing the faulty mosfet, the technician proceeded to find a suitable replacement with similar specifications. Through testing and comparing data sheets, a compatible mosfet was selected and successfully installed. Powering on the device resulted in fan spin at eight volts, indicating a successful repair.

Upon reassembly, the 410 Duo powered on correctly, displaying voltage readings and functioning as expected. This detailed diagnostic process underscored the importance of identifying and replacing faulty components to effectively restore functionality to electronic devices.

Finding a Suitable Replacement Component

After identifying the faulty mosfet in the 410 Duo device, the technician needed to find a suitable replacement component with similar specifications. By testing and comparing data sheets, a compatible mosfet was successfully located and installed. The new component allowed the device to power on, with fan spin observed at eight volts, indicating a successful repair.

Through thorough research and testing, the technician was able to identify a mosfet that matched the required specifications, ensuring the proper functioning of the device. By selecting a comparable component, the technician demonstrated the importance of finding the right replacement part to restore functionality to electronic devices effectively.

With the new mosfet in place, the 410 Duo device powered on correctly, displaying voltage readings and operating as expected. This process highlighted the critical role of locating and replacing faulty components to ensure the successful repair of electronic devices.

Replacing the Faulty Component

Upon identifying the faulty mosfet in the 410 Duo device, the technician proceeded to find a suitable replacement component with similar specifications. Through testing and comparing data sheets, a compatible mosfet was successfully located and installed. The new component allowed the device to power on, with fan spin observed at eight volts, indicating a successful repair.

By conducting thorough research and testing, the technician ensured that the selected mosfet matched the required specifications, ultimately leading to the proper functioning of the device. The process of finding a comparable replacement part demonstrated the importance of selecting the right component to restore functionality to electronic devices effectively.

With the new mosfet properly installed, the 410 Duo device powered on correctly, displaying voltage readings and operating as expected. This detailed approach highlighted the critical role of identifying and replacing faulty components in ensuring the successful repair of electronic devices.

Testing the Repaired Device

After replacing the faulty mosfet in the 410 Duo device, the technician proceeded to test the device to ensure it powered on correctly. With the new component in place, the device was powered on, and fan spin was observed at eight volts, indicating a successful repair. The thorough testing process confirmed that the device was functioning as expected, displaying voltage readings and operating correctly.

Once reassembled, the 410 Duo powered on without any issues, showcasing its restored functionality. The successful repair highlighted the importance of thorough testing to ensure that electronic devices are in proper working condition after component replacement. By verifying the functionality of the device post-repair, the technician ensured that the repair process was completed accurately and effectively.

Reassembling the Device

After successfully replacing the faulty mosfet in the 410 Duo device, the technician proceeded to reassemble the device. Carefully putting all the components back together, ensuring proper connections and alignment, the device was reassembled to its original state. Once the reassembly was complete, the technician powered on the device to confirm its functionality.

Upon powering on the 410 Duo, the device displayed voltage readings and operated as expected, indicating that the reassembly process was successful. The thorough reassembly process highlighted the importance of attention to detail and precision in ensuring electronic devices function correctly after repair. By meticulously reconstructing the device, the technician ensured that all components were securely in place and functioning properly.

With the 410 Duo device fully reassembled and functioning correctly, the comprehensive repair process was successfully completed. The meticulous reassembly process emphasized the significance of proper handling and assembly to guarantee the restored functionality and performance of electronic devices post-repair.

Conclusion

Through a detailed step-by-step guide, the technician successfully diagnosed and repaired the 410 Duo device, showcasing the importance of identifying and replacing faulty components. Starting with an initial assessment, the technician identified the issue and located the faulty mosfet causing the device not to power up. By finding a suitable replacement component, testing it, and successfully installing it, the device was restored to full functionality.

The meticulous testing and diagnostic process emphasized the critical role of thorough inspection and component replacement in electronic device repair. Reassembling the device with precision and attention to detail ensured that all components were securely in place, leading to the successful restoration of the 410 Duo. The comprehensive repair process highlighted the significance of proper handling and testing to guarantee the device’s proper functionality post-repair.